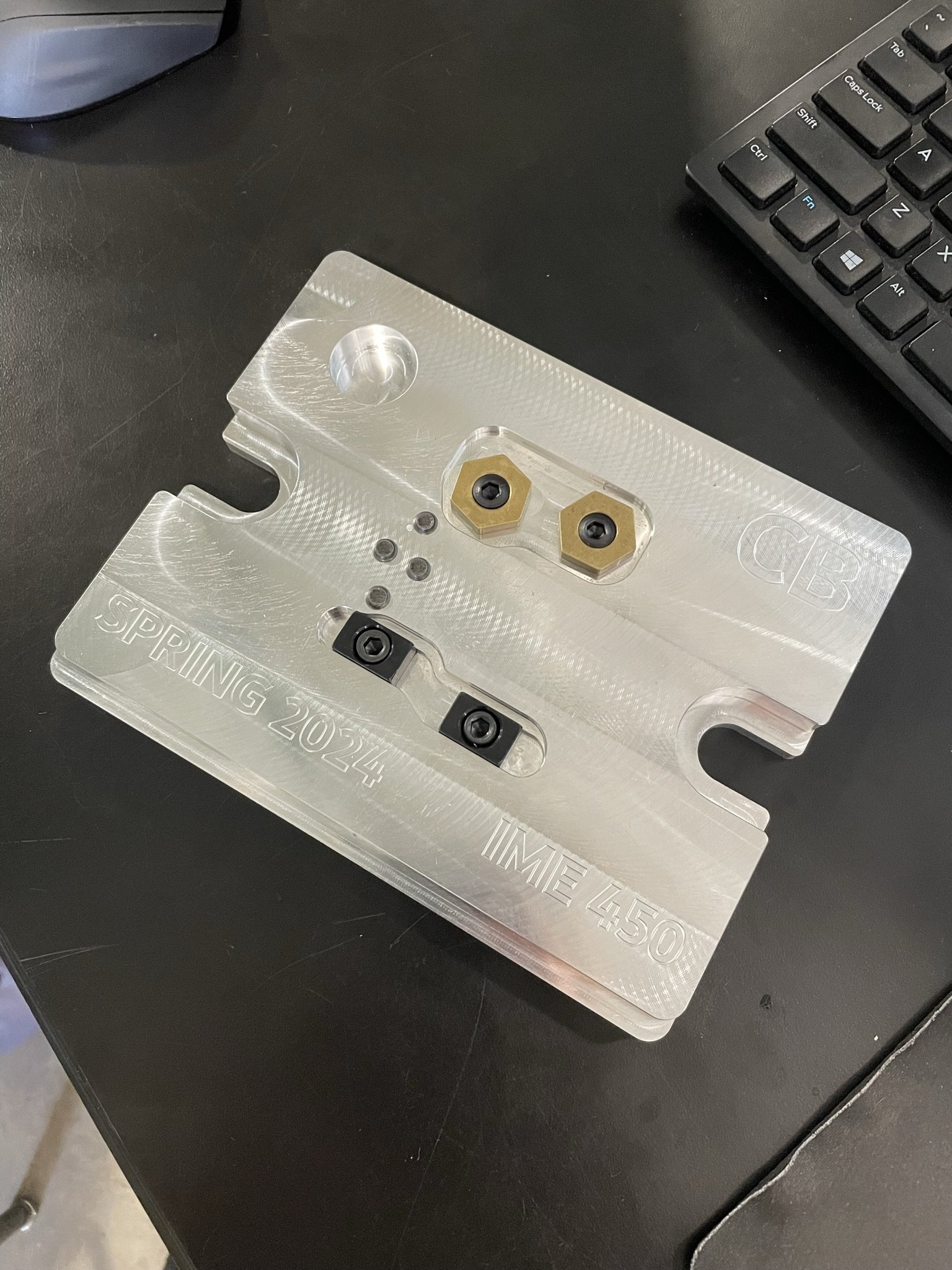

Keychain Fixture Plate

Overview

Completed Spring 2024

This was a class project to design a fixture plate for the second operation of a keychain bottle opener. The goal was to be able to machine a fixture that could properly locate the part according to the GD&T specified on the drawing. The fixture locates the part using a flat, machined face, two Mitee-Bite clamps, and a 1/4 inch pin. There are also three additional pins that check for the MMC condition of the bottle opener, so that time is not wasted machining parts that were out of spec from the first operation. There are reliefs cut around each locating surface to keep chips from blocking the part and causing misalignment. The WCS for machining the keychain is set off of a bore in the plate, and the fixture is squared to the CNC machine using the band cut on the front of the plate. This front indicating surface is recessed to protect it from damage if the plate is ever dropped or bumped. The fixture bolts into the standard t-slots of a CNC mill. The plate was machined out of aluminum on a Haas VF2 CNC mill.